Phone 0161 818 8212 / 07837 905502

steve@absolute-packaging.co.uk Innovation with Simplicity

CASE STUDIES

Home / Case Studies

Case Study One

Furniture

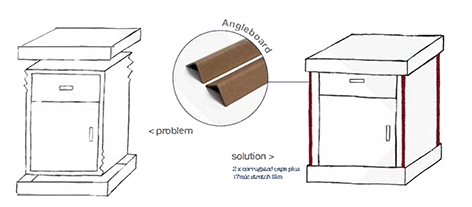

We were approached by a customer manufacturing bedroom furniture who was having a number of issues with product damage on a small pedestal unit, attributed to bad handling by haulier and distribution network. They were seeing a monthly rejection rate of

9% which equated to a cost of over £6,000 in returns for approx. 160 units. In addition to this the cost of admin, return cost, replacement costs amounted to a further £8000 making a total of £14,000 or 18% of sales value.

We conducted on site assessment and monitored transport methods and spent time with the distribution site to Identify where and why the damage was occurring. This highlighted a number of issues. In fact 20% of damage actually occurred in the customers factory, warehouse and despatch. Transport accounted for 18% and the distribution a further 62%.

We trialled a 35 x 35 x 3mm edge protector (angle board) which resolved all of the customer and transport issues resulting in 60 units saved from damage. As distribution could be handled several times this proved more difficult but with the edge protection applied reduced damage by 44% saving a further 70 units.

Initially returns averaged 30 units but has since reduced to 20 units by better working practices. Overall savings of 140 units at a total return/replacement cost of £12,250 per month were saved. The extra cost of edge protection was approx. £700 per month.

Over a 12 month period the saving to this customer was £147,000 for an outlay of less than £10,000.

Case Study Two

Baked Goods

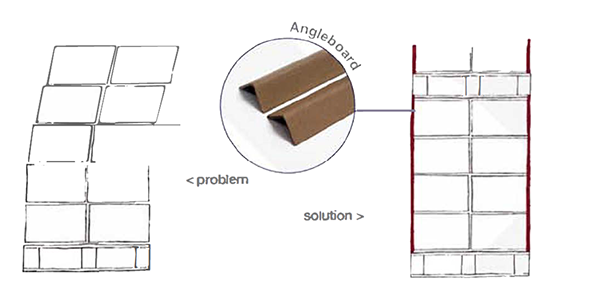

This customer manufactures speciality breads and pastries and distributes them directly to several leading supermarkets.

Although generally the product was light, issues were arising with supermarkets rejecting full lorries as the pallets had slipped/

tilted during transit and due to Health and Safety rules, they could not be off loaded.

Pallets were approx. 1400mm high and were despatched with Just shrink film applied, strapping was tried but rejected by supermarkets due to damage they caused. Cost of each rejection was £2,500 and they were seeing at least one a month sometimes up to three.

After initial assessment and on site visit to

the manufacturing plant and a supermarket delivery we

proposed a two fold solution.

Step one was to introduce a 50 x 50

x 3mm edge protection (angle board)

which would hold the pallet upright.

Step two was to reduce pallet height to 1200mm but

using the edge protection as support this would allow

them to double stack the pallets something they previously

could not do.

This allowed them to overcome the issue of movement in transport and to increase the number per lorry saving them on transport costs and warehouse space for stock awaiting despatch.

Case Study Three

Automotive

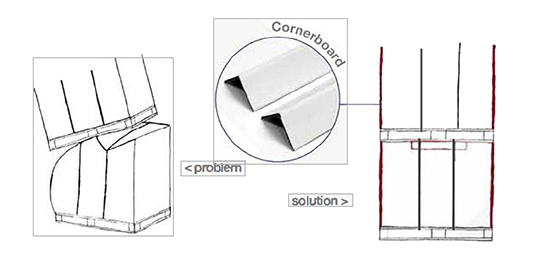

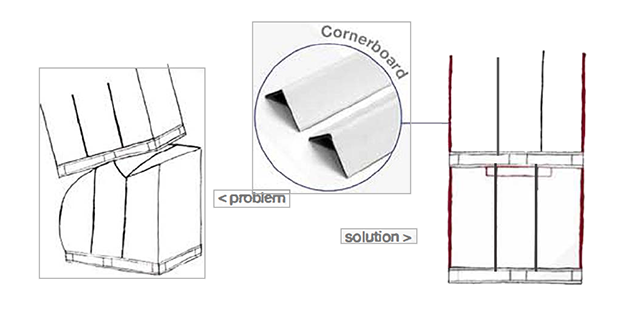

A manufacturer of heavy automotive components had issues with boxes collapsing when double stacking and due to pallets moving the contents were being damaged and some even protruded through the corrugated cases they were packed in. With up to 800kg in each case this would need special consideration.

During initial assessment the heavy boxes were moved several times at the customers plant prior to despatch and the transport journey was usually a few hundred miles. Storage also was a concern as it was often cold and damp.

These conditions combined with the weight involved would make paper products unsuitable. We therefore trialled our composite product

(cornerboard) in a 75 x 75 x 5mm profile.

Transit trials immediately showed an Improvement In stability and although the storage conditions were not Ideal the composition of the cornerboard did not deteriorate even after 12 weeks in storage (Average is 6 weeks).

Out of 140 pallets sent out initially between 5-1 O were rejected, since the introduction of cornerboard they have had no rejections whatsoever.

Case Study Four

Metal Tubes

A client who was manufacturing high value metal tubes was having problems with damage and subsequent returns.

As a large proportion were exporting this was becoming a real financial issue. After an initial meeting it was found that approx. 40% of his output was wrapped In corrugated sheets, steel banding was used and then lape was used along the length, the other 60% was sent out in paper tubes using plastic end caps again with lape applied along the length.

Although there were 3 common lengths, 3200mm. 5000mm and 6700mm there were often different lengths required which meant the tubes used were no good as when cut they tended to de laminate so this Is where the corrugated wrap was used. They had complained to the haulier about the damage being seen but he attributed blame mainly on the movement of the round tubes during transport After on site inspection and transport trial the damage on the tubes was due to their instability being round and the weight of the tubes causing them to rupture at times.

Likewise the corrugated wraps applied

were subject to other products coming into

contact with the packages and the weight in

the package moving during transport.

This seemed an ideal application for our transit packaging system "Reddl Crate•. Looking at the size of the tubes and quantities sent out the client would need two sizes: 120 x 160 x 120mm and

a larger210 x 240 x 210mm. Weight was a vital consideration but to save cost we offered a 4.8mm top and 9.6mm bottom to support weight.

Trials were an immediate success and as Reddi Crates are top loaded this saved packing/despatch time over tubes and wrapping.

The square profile meant there was no movement in transport and damage showed a significant reduction. Where shorter lengths of tubes were to be despatched, Redd! Crate can be cut down from standard lengths to suit.

As part of the solution the Reddi Crate tops were printed with customer details and logo making the pack much more professional in its appearance.

Case Study Five

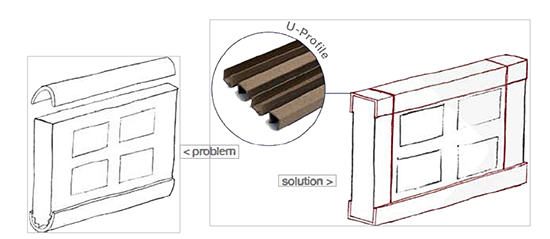

Door and Door Sets

One customer who was moving a heavy board product had issues with the transport companies dropping the product on the corner and damaging the profiled edge. They were using a foam protector which although giving good protection in storage where product on shelving was having contact, the weight of the product meant the foam showed no protection qualities when dropped.

We looked at the Issue closely and as 80% + was sent on courier type transport the problem came with handling where often one man would deliver the product. We suggested the use of our "U Profile" in 3mm thickness.

We conducted on site trials which Included drop tests from 100mm up to 300mm and a drag test over 20 metres.

Our U Profile consistently outperformed the current foam product and also a corrugated option the customer was also looking at.

After two months of transit tests the customer switched to the U profile.

Over his annual production not only were his returns reduced by over 70% and the cost of material was reduced by some 45%.

Case Study Six

Printed Goods

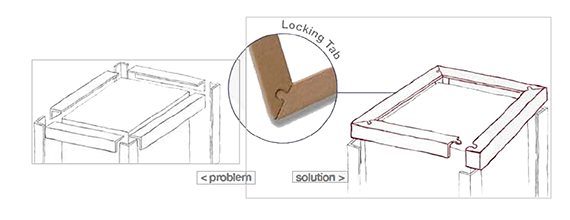

A customer was sending out large volumes of boxed printed material, up to 2,000 pallets per month. To protect the pallets they were using four pieces of edge protection to form a frame around the top boxes on the pallet. They also used four uprights on each of the corners. They had tried self adhesive tape but this was found to damage the printed boxes and so was discounted.

The issue was the time and manpower it took to pack each pallet as they applied the four pieces by taping them together and then inserting the uprights before the pallet was shrink wrapped.

Each pallet took around five minutes to pack often requiring two packers equating to 330 hours/ £4,125 per month.

We considered various options and put forward our new locking tab edge protector which was supplied In one length and creased at specific points to told around the pallet very easily. This was an immediate success.

After initial familiarisation. the packing time was reduced to under three minutes - a 40% time saving and In monetary terms providing a saving of £39,500. some 45%.

In association with our manufacturing plants, our objectives are simple, innovation with simplicity. Offering different styles of packaging from plain to full colour. Adhesive tapes printed/plain shrink and bubble wrap with next day delivery from stock to accompany your new packaging.

Absolute Packaging Limited

VAT Number: 124983986

Company Registration Number: 07796161

GET IN TOUCH

Phone : 0161 818 8212

07837 905502

Email : steve@absolute-packaging.co.uk

Office : Unit 2 Bird Hall Lane, SK3 0SZ

Terms and Conditions of Sale